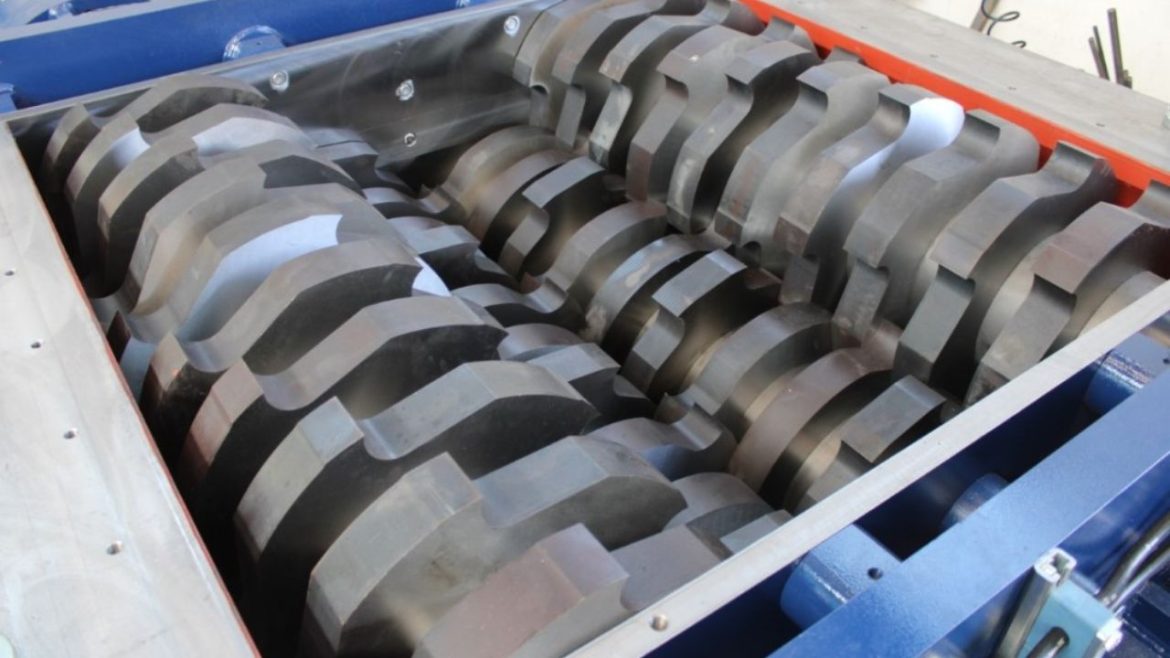

The correct choice of the blade is one of the foundations of the effective work of the shredder, which directly contributes to productivity, energy usage, and the life of the equipment. A wide variety of materials, plastics and metals, wood, textile and municipal solid waste are processed by industrial shredders. The various materials all bring their own problems, whether it is hardness, abrasiveness or a fiber structure, which must be addressed by a particular blade design and material. The choice of the correct shredder blades will make sure that the shredder works steadily, decreases wear, and is safe to operate.

Material Characteristics Dictate Blade Requirements

The type of material that is processed is one of the most important factors that causes the adequate choice of the blade to be a critical issue. The soft coils, which may be made of paper, textile or foam, need sharp and flexible blades so that they are not clogged and shred evenly. Harder materials like metals, rubber, and thick plastics should be reinforced with tougher and wear-resistant blades to be impacted repeatedly without chipping or deforming. This can lead to an overall failure to match the type of blade to the material, and this could lead to inefficient cutting, increased energy consumption and increased wear and tear, leading to expensive maintenance and unforeseen idle time.

Impact on Efficiency and Throughput

The effectiveness of a shredder is directly associated with the suitability of the blades for the material they are supposed to be used on. Properly chosen blades minimize resistance in shredding so that the machine runs at peak speed and torque. This results in the rapid processing time, uniform particle size and other downstream processes like screening or sorting. On the contrary, using the wrong blades may cause the machine to operate slowly, produce irregular material sizes and even jam or overload. These inefficiencies, in the long-run, compound to decrease the overall throughput and impact on the manufacturing timetables.

Reducing Wear and Maintenance Costs

One of the greatest operational costs of industrial shredding is blade wear. Incorrect blade material or design may wear out early, break off or become dull easily, and hence it needs to be replaced frequently. The determination of the right blade, taking into account the factors of hardness of the material and the processing conditions, prolongs the life of the blade and lowers the rate of maintenance. Blades with high quality and a specific application purpose spread the cutting forces equally and reduce the stress on the shafts and frames of the shredder. This will not only reduce the replacement cost but also the chances of equipment damage, thus the entire shredder system will serve longer.

Customization for Specialized Applications

The industrial shredder has applications in various industries, and it is applied in recycling, forestry, agriculture and municipal waste management. The materials of each sector might have specific qualities, e.g., fibrous textile, coated plastics or mixed metal waste. These specialized requirements are met by the proper choice of blade, including blade shape, thickness, edge geometry, and alloy composition. The opportunities of numerous manufacturers to customize the blades also enable their clients to optimize them according to their machines and materials. Such customization guarantees the highest efficiency, uniformity and dependability even in hard-to-operate environments.

Economic Implications

The economic effect of an appropriate choice of the blade cannot be overestimated. Effective shredding saves energy and maximises throughput and minimises maintenance costs, which are all that can be attributed to a healthier bottom line. Conversely, high operational costs are caused by frequent replacement of the blades, unexpected downtime, and ineffective processing. One of the cost-effective strategies that will improve the performance of the machine, increase the lifespan of equipment, and provide a stable and high-quality output is investing in a suitable blade to use in a particular material.

Conclusion

The selection of the proper blade is critical to the attainment of maximum shredder performance, operation efficiency, and safety. Through the use of matching blade type, material, and design with the particular needs of the material being worked, operators are able to maximize throughput, minimize wear and downtime. The correct blades will guarantee a consistent cutting performance and prevent equipment and personnel damage regardless of being in recycling, forestry, agriculture, or industrial waste management. The bottom line is that making an investment in terms of time and resources in picking the right shredder blades eventually leads to increased productivity, lower expenses and eventual long-term success of any shredding process.